Login

Contact

Description

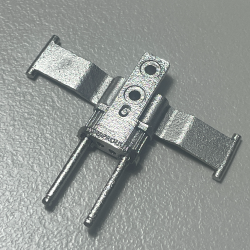

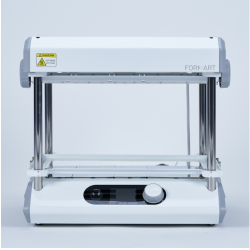

Dual Feed Single Nozzle Design

Patented 2-in-1 Dual Output Nozzle

Our patented 2-in-1 dual output nozzle allows for easier removal of support structures and unparalleled mixed color gradient effects. Available in nozzle diameters from 0.25mm to 1.0mm, it adapts to any project.

Instant Dual Material Switching

We have minimized the mixing zone to just 0.4 cubic millimeters, enabling your 3D printer to switch between two materials instantly.

2-in-1 Nozzle vs. 2-in-2 Nozzle

Simplified Calibration and Perfect Alignment

Traditional 2-in-2 dual nozzle printers require complex calibration to avoid misalignment and properly combine different materials. PING’s large dual-material 3D printer features a patented 2-in-1 nozzle that mixes materials at the nozzle tip, ensuring perfect alignment of the two materials.

Automatic Feeding and Retraction

Intuitive Control System

The intuitive control system simplifies the setup for material feeding and retraction, enhancing print quality.

Industry-Leading Precision for Dual Material Mixing

Patent-Pending Nozzle Design

PING’s patented nozzle design can print two materials through a single nozzle, achieving extreme precision and eliminating alignment errors. Materials mix as they extrude from the nozzle, providing maximum control and accuracy. With PING’s 3D printer, you can print internal moving parts and tiny components that traditional 3D printers or injection molding machines cannot achieve.

Easy Support Removal

Quick and Clean Support Detachment

Say goodbye to lengthy sanding, filing, and trimming. Our patented nozzle technology allows you to easily and quickly remove supports, ensuring smooth object surfaces. The 2-in-1 nozzle design guarantees high-precision material placement, ensuring supports can be removed smoothly without residue.

Whether you are prototyping or producing small batches, eliminating complex support removal steps reduces damage risk and enhances the visual appeal of your objects.

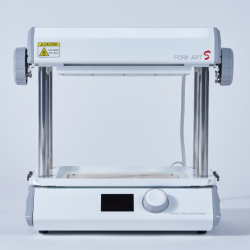

Patented 2-in-1 Dual Output Nozzle

Our patented 2-in-1 dual output nozzle allows for easier removal of support structures and unparalleled mixed color gradient effects. Available in nozzle diameters from 0.25mm to 1.0mm, it adapts to any project.

Instant Dual Material Switching

We have minimized the mixing zone to just 0.4 cubic millimeters, enabling your 3D printer to switch between two materials instantly.

2-in-1 Nozzle vs. 2-in-2 Nozzle

Simplified Calibration and Perfect Alignment

Traditional 2-in-2 dual nozzle printers require complex calibration to avoid misalignment and properly combine different materials. PING’s large dual-material 3D printer features a patented 2-in-1 nozzle that mixes materials at the nozzle tip, ensuring perfect alignment of the two materials.

Automatic Feeding and Retraction

Intuitive Control System

The intuitive control system simplifies the setup for material feeding and retraction, enhancing print quality.

Industry-Leading Precision for Dual Material Mixing

Patent-Pending Nozzle Design

PING’s patented nozzle design can print two materials through a single nozzle, achieving extreme precision and eliminating alignment errors. Materials mix as they extrude from the nozzle, providing maximum control and accuracy. With PING’s 3D printer, you can print internal moving parts and tiny components that traditional 3D printers or injection molding machines cannot achieve.

Easy Support Removal

Quick and Clean Support Detachment

Say goodbye to lengthy sanding, filing, and trimming. Our patented nozzle technology allows you to easily and quickly remove supports, ensuring smooth object surfaces. The 2-in-1 nozzle design guarantees high-precision material placement, ensuring supports can be removed smoothly without residue.

Whether you are prototyping or producing small batches, eliminating complex support removal steps reduces damage risk and enhances the visual appeal of your objects.

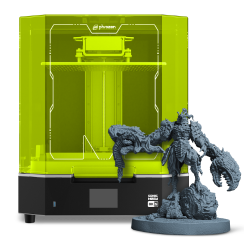

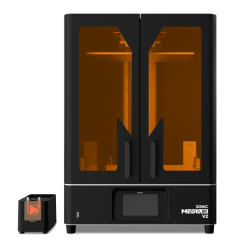

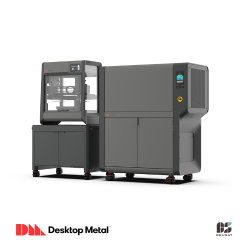

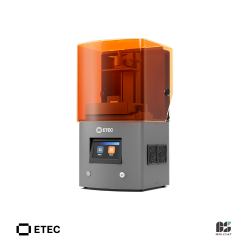

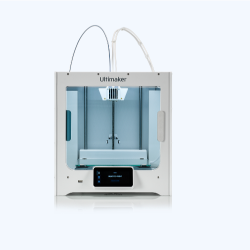

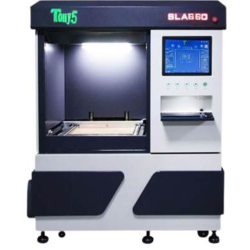

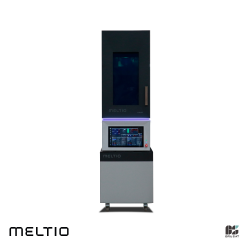

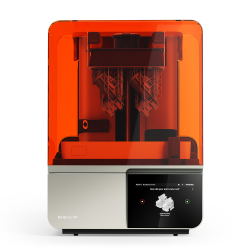

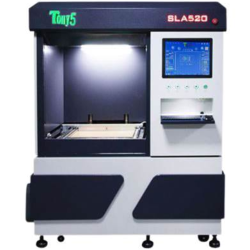

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry